Machine elements – basics

Overall Course Objectives

The aim of this course is to give the students :

– An overview of the most basic machine components.

– The fundamental insight making them able to dimension and select appropriate machine components for a mechanical design based on requirements to the component.

– A basic understanding of the working principles of the components.

– An overview of the methods for analysis and design of selected machine components.

– An understanding of the failure mechanisms for the machine components.

See course description in Danish

Learning Objectives

- Describe capabilities and characteristics for a number of basic machine elements.

- Elaborate on the working conditions and other operating conditions for components in a mechanical product.

- Identify components which are critically loaded.

- Describe and utilize the models and analysis methods, which forms the base for selecting basic components.

- Utilize mechanics and strength of materials when dimensioning machine elements.

- State requirements to materials and functional surfaces for components in a mechanical product.

- Use the standards, which describes the frame for dimensioning of machine elements, including DS-, DIN-, EN-, and ISO-Standards.

- Specify tolerance requirements to machine elements and mechanical systems.

- Read and understand literature in the machine element field.

Course Content

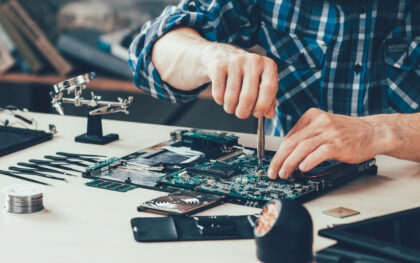

Analysis and dimensioning of the most commonly used machine components.

Assembly methods. Bolted joints. Geometrically locked and frictionally locked shaft-hub connections, including keys and cotters, springs, splines, and interference fits.

Elastic elements, helical springs, spiral springs, conical disk springs and rubber springs.

Shaft design and dimensioning.

Bearings. Analysis methods for the selection of rolling element bearings. Introduction to hydrodynamic bearings.

The specification and analysis of tolerances and fits based on requirements to the component function. Geometrical tolerancing (Geometrical product specifikation).

Teaching Method

Lessons and problem solving.