Design, fabrication and characterization of optical planar waveguide components

Overall Course Objectives

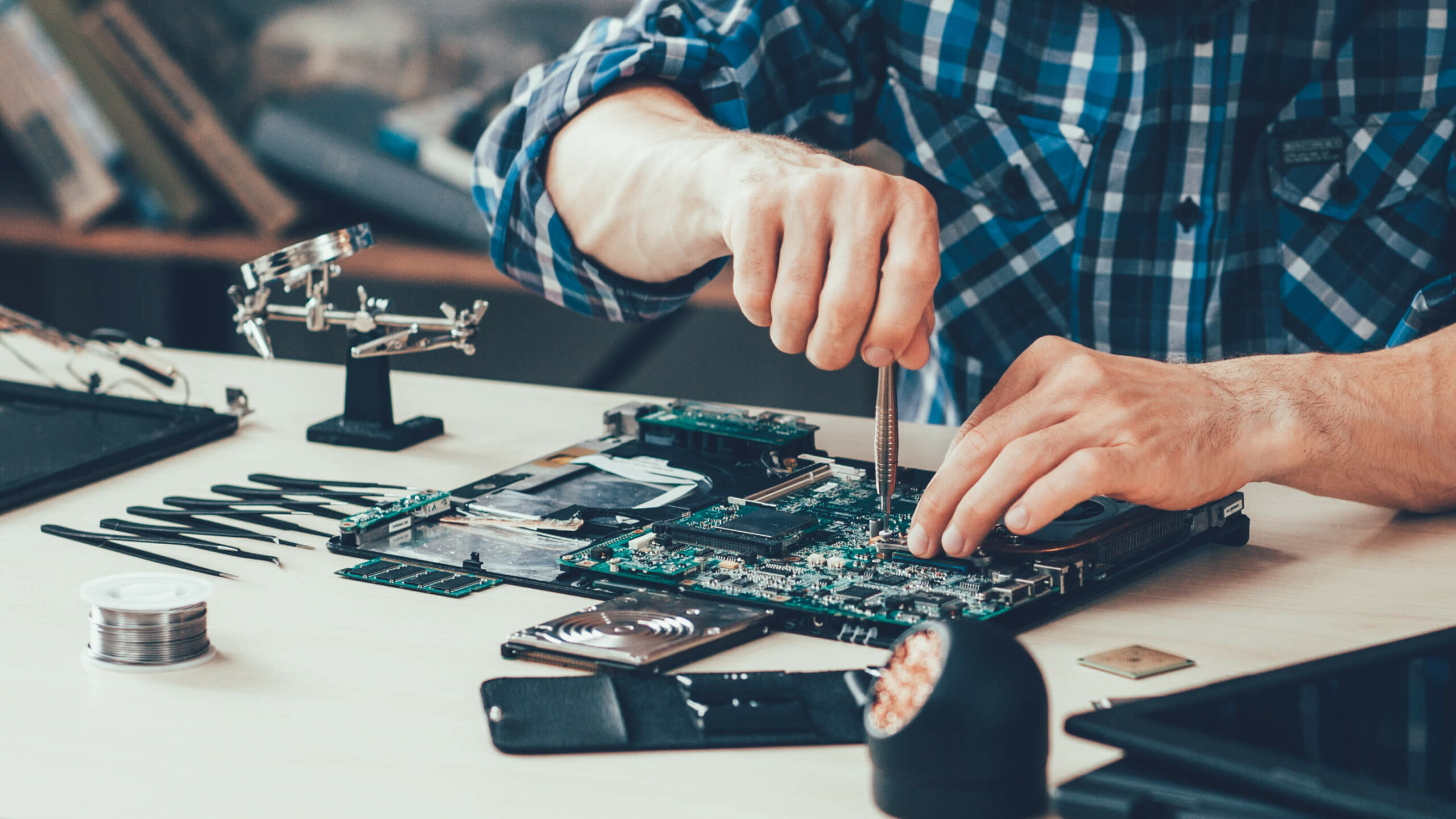

The course aims at introducing all around basic components (physical concept, equipment and software) from design to fabrication and characterization of silicon optical planar waveguide components through hands-on experience

Learning Objectives

- Work confidently in the cleanroom

- Select proper material platform for different applications in integrated optics

- Design processing flows for device fabrication

- Interpret and optimize key processing steps in the fabrication of waveguide components

- Align fibers with nanoscale waveguides efficiently

- Handle chips and fibres with skills of dicing, cleaning and cleaving etc.

- Set up simple optical measurements

- Do component simulation and mask layout by using commercial softwares

- Describe working principles of waveguide components

- Apply knowledges to current waveguide components research and application

Course Content

• Learn rules of working in the cleanroom

• Get familiar with key processings in the cleanroom, including film deposition, lithography and etching

• Build models of waveguides to simulate effective refractive index, coupling loss etc using commercial software

• Make mask layout using commercial software L-edit/Clewin

• Do electron-beam lithography, including resist spin, e-beam exposure and developing

• Operate ”advanced silicon etcher ” (ASE) and edit recipes for silicon etching

• Investigate the nanoscale features using scanning electron microscope (SEM)

• Couple light in and out of waveguide components on 3-dimentional stages

• Set up simple measurement circuits including light source, polarization controller and optical spectral analyzer (OSA) to measure propagation loss of straight waveguide by cutback method

• Setup OSA correctly with regard to resolution, sensitivity, average, sampling, and configure OSA and TLS to work in synchronization

• Measure silicon micro-ring resonators and analyze the difference between the design and the measured values

Recommended prerequisites

Teaching Method

The students will work in groups on topics related to waveguide components: designing using commercial software, fabrication using the state-of-art cleanroom facilities at Nanolab, and characterization in the lab.

Faculty

Limited number of seats

Minimum: 3, Maximum: 9.

Please be aware that this course has a minimum requirement for the number of participants needed, in order for it to be held. If these requirements are not met, then the course will not be held. Furthermore, there is a limited number of seats available. If there are too many applicants, a pool will be created for the remainder of the qualified applicants, and they will be selected at random. You will be informed 8 days before the start of the course, whether you have been allocated a spot.